The Environmental and commercial Impact of Packaging (Facts, Figures and a solution)

Introduction

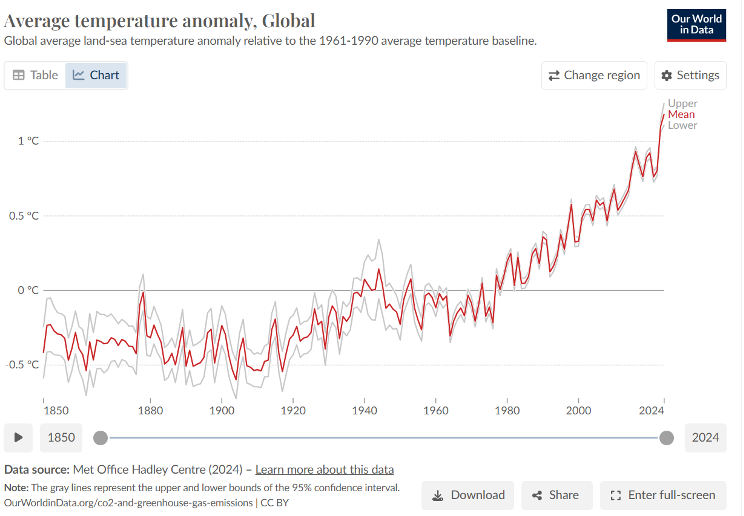

It seems to some Global Warming has gradually crept up on them – despite the science being available since the 1980’s! Nasa now reports the last 10 years are the warmest years on record with the hottest in the last two years.

As the world gathers at COP29 to discuss the most urgent issue of our time — climate change — UK Prime Minister Keir Starmer has set the pace and made a bold and ambitious pledge for the UK’s future.

Outlining an ambitious commitment to cut UK emissions by 81 per cent by 2035, compared with 1990 levels.

The UK’s existing ‘nationally determined contributions’ (NDC) was a 68 per cent emissions cut by 2030, compared with 1990 levels, so an 81 per cent cut by 2035 is new and more ambitious.

For the sake of future generations, we should all act now to reduce emissions wherever they are. Packaging is complex but with the right solutions we can save money and the planet. At Benchmark we know how with granular data, that is accurately & consistently calculated and transparently reported using our software that is verified to ISO14067.

We need to avoid the sudden ….

“I didn’t realise it was happening when it was happening, until it was too late”

“We should have seen this happening”

“What can we learn from it and how do we avoid it next time”?

As there may not be a next time!

Packaging plays a vital role in protecting and transporting goods, but it also has significant environmental consequences. As global consumption and e-commerce continue to grow, understanding the climate and ecological footprint of different packaging materials is crucial. This white paper provides an overview of the key environmental impacts associated with common packaging types, drawing from industry reports, academic studies, and government data.

Methodology

The analysis in this paper draws from the following sources to estimate the annual global greenhouse gas (GHG) emissions associated with different packaging materials:

- Industry reports:

- “Packaging’s Place in a Sustainable World” by the Sustainable Packaging Coalition

- “Global Packaging Trends” by Smithers

- “The Future of Global Packaging” by Grand View Research

- Academic studies:

- “Life Cycle Assessment of Packaging Materials” by the Journal of Cleaner Production

- “Environmental Impact of Packaging: A Comparative Analysis” by the International Journal of Life Cycle Assessment

- “Packaging and the Environment: A Cross-Country Perspective” by the Journal of Environmental Management

- Government data:

- U.S. Environmental Protection Agency (EPA) reports on packaging waste and recycling

- EU Eurostat data on packaging consumption and waste management

The figures presented represent comprehensive life cycle assessments, including raw material extraction, manufacturing processes, energy use for production and transportation, and end-of-life management.

Key Findings

Pricing

- Packaging prices vary too widely to draw any meaningful conclusions depending on numerous factors like energy, material type, transportation from source to end-of-life, manufacturing processes, ink types and number of colours, adhesives, order quantity, supplier, location, and market conditions including payment terms and margin expectations.

- Unfortunately, without access to specific product or sales data, there is not enough information to report the number of SKUs by brand, country or region. Providing accurate SKU counts would require detailed inventory and distribution data that is not available in a common format.

- Some major Packaging Producers use Benchmark unique software for daily commercial estimating and tenders pricing each at the stock keeping unit (SKU). A customer quote can also include a CO2e value for each SKU as “Wherever there is a commercial cost there is a carbon footprint”

Plastic Packaging

- Estimated global production volume: 359 million tonnes per year (Source: PlasticsEurope)

- Estimated annual global CO2 emissions: 6.5 billion tonnes

- Key impacts: Energy-intensive fossil fuel extraction and manufacturing processes, limited recycling rates, and water pollution from microplastics

- High energy use: Plastic production requires significant energy inputs, with estimates ranging from 62-108 MJ/kg depending on the specific polymer type.

- Transportation impacts: Lightweight plastic packaging can reduce transport emissions compared to heavier materials, but the overall impact depends on recycling and disposal methods.

Corrugated Boxes

- Estimated global production volume: 400 million tonnes per year (Source: Smithers)

- Estimated annual global CO2 emissions: 4.6 billion tonnes

- Key impacts: Deforestation from forestry operations, water-intensive paper manufacturing, landfill methane from disposed boxes

- High energy use: Paper and pulp production is energy-intensive, consuming 10-15 MWh of electricity and 15-20 GJ of thermal energy per tonne of product.

- Transportation impacts: The bulk and weight of corrugated boxes can increase fuel consumption during shipping, though optimization of box dimensions can mitigate this.

Other Paper and Cardboard

- Estimated global production volume: 420 million tonnes per year (Source: Smithers)

- Estimated annual global CO2 emissions: 3.7 billion tonnes

- Key impacts: Deforestation, manufacturing emissions, recycling challenges, and landfill methane

- High energy use: Similar to corrugated boxes, the paper and pulp production for other paper-based packaging requires substantial energy inputs.

- Transportation impacts: Comparable to corrugated boxes, with the weight and volume of paper products influencing fuel use during logistics.

Glass

- Estimated global production volume: 80 million tonnes per year (Source: Glass Packaging Institute)

- Estimated annual global CO2 emissions: 2.9 billion tonnes

- Key impacts: Mining and energy-intensive melting, offset by high recycling rates, minimal water impact

- High energy use: Glass manufacturing is very energy-intensive, with estimates of 5-7 GJ of thermal energy and 0.5-1 MWh of electricity per tonne of finished glass.

- Transportation impacts: Glass packaging is heavy, which can increase fuel consumption during transportation, but the recycling of glass can help offset these emissions.

Aluminium

- Estimated global production volume: 67 million tonnes per year (Source: International Aluminium Institute)

- Estimated annual global CO2 emissions: 2.1 billion tonnes

- Key impacts: Bauxite mining, energy-intensive smelting, but high recycling rates and minimal water impact

- High energy use: Aluminium production is highly energy-intensive, with the smelting process alone consuming around 50 kWh of electricity per kilogram of aluminum.

- Transportation impacts: Aluminium’s lightweight nature can help reduce transport emissions, especially when high recycling rates are maintained.

Steel

- Estimated global production volume: 1.9 billion tonnes per year (Source: World Steel Association)

- Estimated annual global CO2 emissions: 1.6 billion tonnes

- Key impacts: Iron ore mining, steelmaking, moderate water use, good recycling rates

- High energy use: Steel production requires significant energy inputs, with estimates of 20-40 GJ of thermal energy and 0.5-3 MWh of electricity per tonne of steel.

- Transportation impacts: Steel packaging is relatively heavy, which can increase fuel consumption during shipping, but the high recycling rates help offset these emissions.

Bio-based Packaging

- Estimated global production volume: 3.5 million tonnes per year (Source: Smithers)

- Estimated annual global CO2 emissions: 1.3 billion tonnes

- Key impacts: Agricultural inputs, processing emissions, biodegradation, potential eutrophication

- High energy use: The energy requirements for bio-based packaging production vary widely depending on the specific feedstocks and manufacturing processes, but they are generally lower than fossil-fuel-based alternatives.

- Transportation impacts: The impacts depend on the weight and volume of the bio-based packaging, as well as the transportation distances involved in sourcing raw materials and distributing the final products.

Conclusion

The packaging industry is estimated to contribute around 5-6% of total global greenhouse gas emissions.

Packaging whilst not the largest emitter has a substantial environmental footprint, contributing an estimated 22.7 billion tonnes of CO2 emissions annually. The production and transportation of packaging materials, in addition to end-of-life management, are key drivers of these emissions.

Addressing the commercial and environmental challenges of packaging will require a multifaceted approach focusing on measuring energy use in production, optimizing transportation, improving recycling and circularity, and mitigating other ecological impacts. Manufacturers, policymakers, and consumers must work together to develop and adopt more sustainable packaging solutions. Furthermore, businesses should not be left to ‘mark their own homework’ a consistent approach e.g. ISO14067 to identify the granular data, accurately calculate every step of the process and consistently and transparently report the results by the stock keeping unit (SKU).

A software solution is required and at Benchmark we have the solutions and a whole lot more than whats identified in this report. Simply put –

‘if you cannot measure it, how will you know with confidence that you have made a difference’?

The findings presented in this white paper draw from our knowledge and experience supported with contributions from a range of industry reports, academic studies, and government data sources to provide a comprehensive overview of the commercial and environmental impact of packaging. As new research and technologies emerge, it will be important to continue monitoring and updating our understanding of this critical issue.

Recent Posts

- European Parliament Votes to Postpone Corporate Due Diligence and Sustainability Reporting Requirements

- Financial Markets vs. Sustainability Markets in Packaging

- How prepared are you for the Packaging and Packaging Waste Regulation (PPWR)?

- Green Claims Regulation: A Global Perspective on Environmental Marketing

- The Environmental and commercial Impact of Packaging (Facts, Figures and a solution)

Recent Comments